Customize

About Item

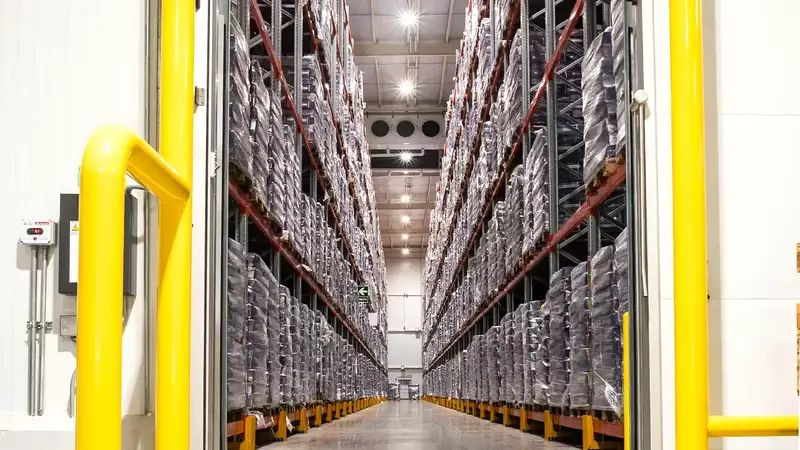

Warehouse Racking & Pallet Rack Maintenance is an agri-focused service designed to inspect, repair, and maintain storage racking systems used in agricultural warehouses and cold storages. This service ensures safe load storage, structural stability, and compliance with safety standards.

Service Overview

Racking systems are critical for organizing and storing agricultural goods such as grain bags, crates, cartons, and packaged produce. Over time, racks may suffer damage due to overloading, forklift impact, corrosion, or misalignment, posing serious safety risks if not addressed.

Warehouse Racking & Pallet Rack Maintenance ensures racking systems remain structurally sound and safe for continued use.

Scope of Work

Inspection of upright frames and beams

Checking load-bearing capacity and alignment

Detection of bends, cracks, and corrosion

Tightening or replacement of connectors and anchors

Safety signage and load marking verification

Racking Systems Covered

Selective pallet racking

Drive-in / drive-through racking

Cantilever racking

Cold storage racking systems

Heavy-duty agri warehouse shelving

Maintenance Methodology

Preventive and corrective maintenance approach

Repair or replacement of damaged components

Realignment and leveling of racks

Anchoring and stability reinforcement

Post-maintenance safety inspection

Operational & Safety Benefits

Prevents rack collapse and accidents

Ensures safe storage of agricultural goods

Improves space utilization and organization

Extends racking system lifespan

Quality & Safety Standards

Inspected by trained racking safety professionals

Complies with warehouse safety guidelines

Uses compatible racking components

Suitable for food-grade and cold storage environments

Importance in Agri Warehousing

Safe and well-maintained racking systems are essential for efficient and secure storage of agricultural products. This service protects goods, equipment, and personnel while supporting smooth warehouse operations.