Customize

About Item

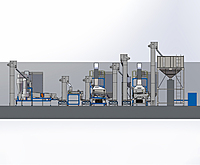

Seed Processing Unit Cleaning is an agri-grade sanitation service focused on maintaining hygienic conditions in seed handling, processing, and storage facilities. This service helps prevent contamination, maintains seed purity, and supports high germination quality.

Service Overview

Seed processing units handle seeds that are highly sensitive to contamination, moisture, and microbial presence. Dust, seed residues, and debris accumulation can affect seed quality, reduce germination rates, and cause cross-contamination between varieties.

Seed Processing Unit Cleaning ensures a clean and controlled environment throughout the processing chain, supporting quality seed production and storage.

Scope of Work

Cleaning of seed processing floors and walls

Removal of seed dust and residues

Sanitation of grading, sorting, and packaging areas

Cleaning of storage bins and workstations

Waste and residue disposal support

Areas Covered

Seed receiving and cleaning zones

Grading and sorting sections

Packaging and labeling areas

Temporary seed storage rooms

Entry points and worker movement zones

Cleaning & Sanitation Methodology

Dry cleaning to control dust dispersion

Controlled wet cleaning where required

Use of agri-safe and seed-compatible disinfectants

Targeted sanitation of high-risk zones

Final hygiene inspection

Seed Quality & Operational Benefits

Prevents cross-contamination between seed lots

Maintains seed purity and quality

Reduces microbial and fungal risks

Improves storage life and handling safety

Quality & Safety Standards

Uses agriculture-approved cleaning agents

Safe for seed handling environments

Performed by trained sanitation personnel

Aligned with seed industry hygiene standards

Importance in Seed Processing Operations

Clean seed processing units are essential for producing high-quality seeds with reliable germination performance. This service supports seed certification, customer trust, and long-term storage quality.