Customize

About Item

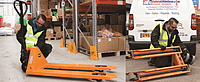

Pallet Truck Maintenance (Manual & Electric) is a specialized service for maintaining pallet handling equipment used in agricultural warehouses, packhouses, and cold storages. This service ensures smooth movement of palletized agri produce with improved safety and reliability.

Service Overview

Pallet trucks are essential material handling tools in agri warehouses for moving grain bags, cartons, crates, and palletized produce over short distances. Continuous usage, heavy loads, and exposure to dust, moisture, or cold environments can lead to wear and reduced efficiency if not maintained properly.

Pallet Truck Maintenance (Manual & Electric) provides systematic inspection and servicing to ensure uninterrupted operations and safe handling of agricultural goods.

Scope of Work

Inspection of forks, frame, and load wheels

Hydraulic system inspection and oil replacement

Steering and handle mechanism servicing

Brake and safety mechanism checks (electric models)

Battery and charger inspection (electric pallet trucks)

Pallet Truck Types Covered

Manual hand pallet trucks

Electric pallet trucks

Low-profile pallet trucks

Cold storage–compatible pallet trucks

Heavy-duty pallet handling units

Maintenance Methodology

Preventive maintenance as per usage conditions

Lubrication of moving components

Hydraulic pressure testing

Replacement of worn seals, wheels, and bearings

Functional testing under working load

Operational & Safety Benefits

Smooth and effortless pallet movement

Reduced risk of load imbalance and accidents

Extended equipment life

Improved productivity in agri warehouses

Quality & Safety Standards

Performed by trained service technicians

Use of compatible spares and hydraulic oils

Safe for food-grade and agri environments

Compliance with warehouse safety practices

Importance in Agri Material Handling

Well-maintained pallet trucks ensure efficient internal movement of agricultural produce, reduce manual strain, and prevent handling damage—making them vital for smooth warehouse operations.