Customize

About Item

Service Overview

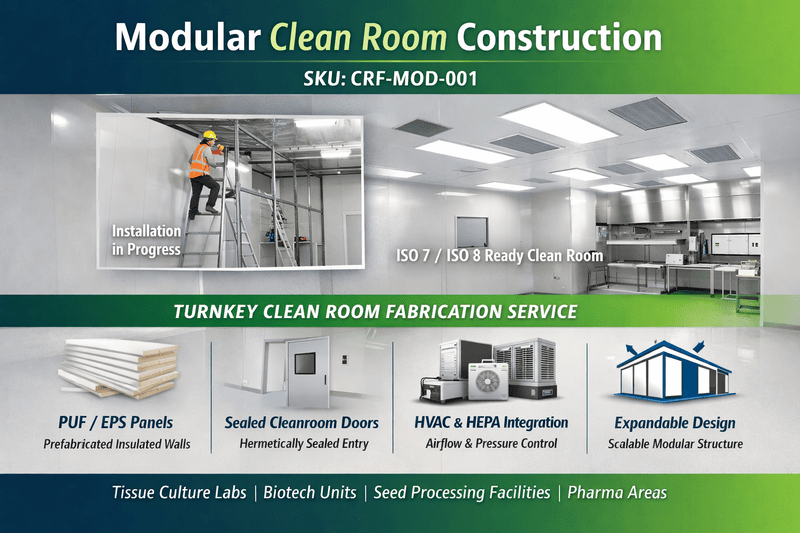

Our Modular Clean Room Construction service provides turnkey fabrication and installation of contamination-controlled environments using prefabricated insulated sandwich panel systems.

Designed for tissue culture labs, biotech facilities, seed processing units, and controlled agri-production zones, this service delivers faster installation, scalable expansion, and compliance-ready infrastructure.

This is a fully customizable service tailored to your layout, process flow, and classification requirements.

Scope of Work

1️⃣ Design & Planning

Site assessment & feasibility review

Workflow-based clean room layout planning

Pressure zoning & airflow pathway design

ISO classification planning (ISO 8 / ISO 7 ready)

2️⃣ Structural Fabrication

PUF / EPS insulated sandwich panels (50–100mm)

Powder-coated / GI support framework

Air-tight modular wall & ceiling integration

Seamless corner & coving finishing

3️⃣ Ceiling & Air Integration

Clean room ceiling grid system

HEPA filter provision compatibility

AHU duct routing provision

Lighting panel placement layout

4️⃣ Door & Partition Integration

Hermetically sealed clean room doors

Interlock provision (optional)

Double-glazed vision panels

Airlock / gowning room partition support

5️⃣ Utility Coordination

Electrical raceway routing provision

HVAC coordination support

Pressure cascade layout readiness

Drainage & service penetration sealing

🔹 Technical Features

Smooth, non-porous, anti-fungal surfaces

Leak-resistant panel joints

Positive / negative pressure compatible

Energy-efficient insulated envelope

Expandable modular structure

Easy dismantling & relocation (optional configuration)

🔹 Applications

Plant tissue culture labs

Mushroom spawn laboratories

Seed processing clean zones

Agri-biotech research labs

Pharmaceutical support clean areas

🔹 Key Benefits

✔ 40–60% faster installation than civil construction

✔ Lower structural load

✔ Scalable & expandable design

✔ Reduced contamination risk

✔ Easy cleaning & maintenance

✔ Subsidy-aligned infrastructure readiness

🔹 Project Execution Model

Technical discussion & requirement gathering

Layout & technical drawing submission

BOQ & cost estimation

Fabrication & material mobilization

On-site installation

Final inspection & handover

🔹 Customization Options

ISO 7 / ISO 8 classification

GMP-aligned construction

Fire-rated panels

Anti-static flooring integration

Advanced monitoring integration